The current state of steel production involves the extensive use of coal as the primary raw material, resulting in significant CO₂ emissions. Within Japan’s total CO₂ emissions, the steel industry accounts for approximately 12%, with blast furnaces contributing the most at 40% of the sector’s total. To reduce CO₂ emissions, measures such as charging scrap steel into converters for refining have been implemented. The amount of scrap steel charged into converters has been increasing annually.

The furnace wall directly impacted by scrap steel entering the converter is termed the charging side wall. As shown in Figure 1, this wall is located where scrap steel and molten iron come into contact. Consequently, the charging side wall suffers mechanical impact and wear from falling scrap steel. The greater the scrap steel input, the more severe the damage compared to standard furnace walls. Furthermore, scrap steel includes heavy scrap pieces weighing over 500 kg each. As the usage of heavy scrap increases, the rate of damage accelerates.

Therefore, impact tests were conducted using magnesium-carbon bricks to confirm the extent of brick damage. Based on this, potential brick damage in industrial furnaces was predicted, leading to the development of new materials tested in industrial furnaces.

1.Drop Impact Test for Scrap Steel

1.1 Test Method

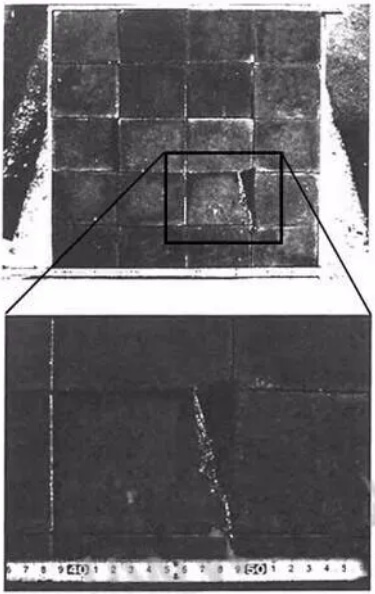

A scrap steel drop impact test was conducted using magnesia-carbon bricks. A simplified diagram of the test is shown in Figure 1. The test used high-strength bricks fired at 1200℃ for 3 hours using reduction firing. The bricks were 100mm × 80mm × 400mm in shape, and 20 bricks were used in combination. The bricks were fixed with an iron plate, and a 12kg rectangular iron block was used as scrap steel, dropped from a height of 2m onto a surface inclined at a 30° angle. The condition of the bricks was observed through this test.

1.2 Test Results and Analysis

Figure 2 shows a photograph of the brick surface after the test, indicating damage at the impact site. Figure 5 shows a photograph of the brick’s appearance after the impact. As can be seen from the figures, the cracks propagate from the damaged area into the brick.

Based on these results, it can be concluded that the magnesia-carbon bricks used in the charging furnace wall developed cracks upon impact with scrap steel, and were damaged due to crack propagation and connection. There are two ways to reduce this damage: one is to inhibit crack initiation, i.e., increase strength; the other is to inhibit crack propagation, i.e., increase fracture toughness. Based on this hypothesis, research was conducted on improving the strength and fracture toughness of the charging furnace wall material.

2.Magnesia-carbon bricks for charging furnace walls

2.1 High-strength material with added metal

Increasing the strength of magnesia-carbon bricks by adding more metal additives is an effective method. However, increasing the metal additive content reduces thermal shock resistance, so the goal is to achieve the desired effect with the minimum necessary amount of metal additives.

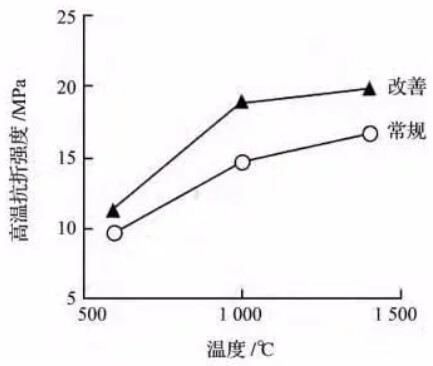

Figure 3 shows evaluation results for magnesia-carbon bricks containing identical types and quantities of metal additives, demonstrating varying high-temperature flexural strengths due to differing additive distribution microstructures. High-strength magnesia-carbon bricks employ this method: by uniformly distributing the metal additives and modifying the microstructure, the metal additives’ effects are effectively harnessed.

2.2 High fracture toughness material for strengthening matrix structure

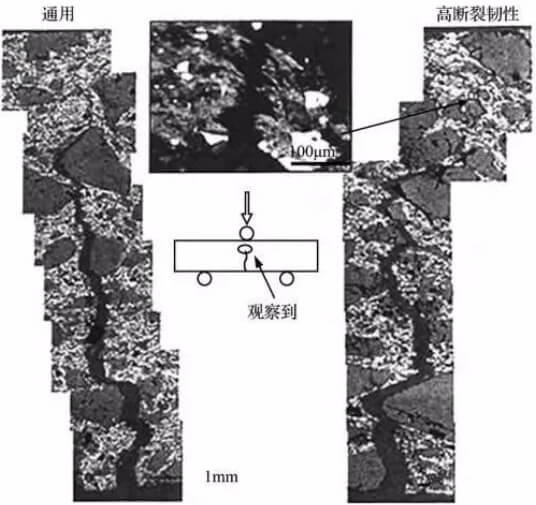

By strengthening the matrix structure and controlling crack propagation, fracture resistance—that is, fracture toughness—can be enhanced. Figure 4 shows the crack propagation path observed in specimens after flexural testing. Crack propagation in matrix-strengthened bricks follows a sawtooth pattern, with macro-crack expansion suppressed. This is generally attributed to crack branching during fracture and the tensile effect of graphite.

2.3 High fracture toughness material with reinforced carbon bonding

As shown in Figure 5, crack propagation occurs by connecting very weak parts of the matrix, such as the MgO particles and graphite, as well as the voids. Therefore, strengthening the weak structures in the matrix can improve resistance to crack propagation. Using pitch to reinforce carbon bonding is an effective method for this purpose.

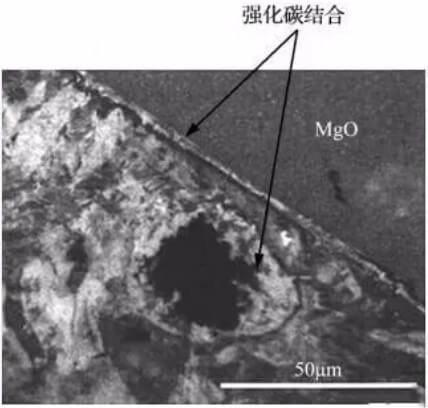

Figure 8 shows a photograph of the structure reinforced with an appropriate amount of bitumen. The bitumen penetrates into the spaces between MgO particles and graphite, as well as the voids, and a carbonized state can be observed. This reinforced carbon-bonded brick, due to the formation of carbon bonds between MgO particles and graphite, strengthens the weak points in the structure, thus improving fracture toughness.

Table 1 lists the typical properties of the three types of magnesia-carbon bricks mentioned above. All samples used raw materials with the same purity.

3.Load-Displacement Curve Determination

3.1 Measurement

The static fracture energy derived from the load-displacement curve was used to evaluate fracture toughness. High-temperature flexural strength was determined from the maximum value of the load-displacement curve. A three-point bending test was conducted with a span of 100 mm and a crosshead speed of 0.1 mm·min⁻¹. Simultaneously with the load measurement, a laser displacement gauge was used to measure the bending displacement at the center of the specimen (directly below the load point), and the load-displacement curve was derived. The specimens were fired in coke powder at 1200℃ for 3 hours and then cut into 40 mm × 15 mm × 150 mm shapes for use. The three-point bending test was conducted at a high temperature of 800℃ in an Ar atmosphere.

3.2 Measurement Results

The increase in displacement relative to the increase in load corresponds to the increase in static elastic modulus, and the peak of the curve represents the point of fracture initiation. Magnesia-carbon bricks contain a large amount of flat, flake graphite, so their resistance to crack propagation is greater than that of ordinary oxide-based bricks. Therefore, ordinary oxide-based refractory bricks experience a rapid release of load after fracture, while magnesia-carbon bricks show a slow decrease in load after crack initiation. The area of the load-displacement curve corresponds to the fracture energy required for crack initiation and propagation; materials with larger areas have higher fracture toughness.

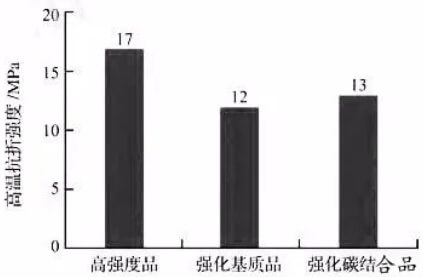

The maximum load applied to high-strength products before cracking occurs represents the highest high-temperature flexural strength. Compared to high-strength products, matrix-reinforced and carbon-reinforced products exhibit lower flexural strength but demonstrate a gradual decrease in load after cracking initiates. Figure 10 shows the high-temperature flexural strength determined through measurement, while Figure 11 presents the fracture energy calculated from the area of the crack propagation region in the load-displacement curve. Both matrix-reinforced and carbon-bonded reinforced products exhibit increased fracture energy, demonstrating excellent fracture toughness as magnesium carbon bricks.

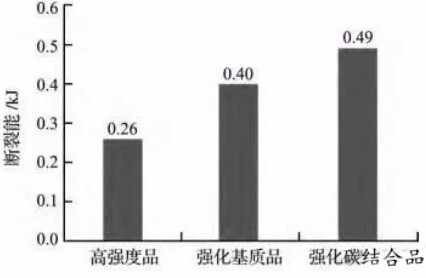

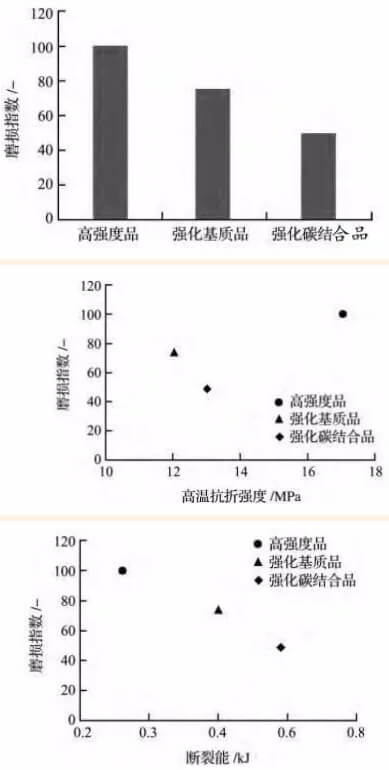

4.Results of using industrial furnaces

The products developed based on the research results are used for the charging side walls of industrial furnaces, and their evaluation results are shown in Figure 12. Figure 12 shows the relationship between the damage rate index and high-temperature flexural strength for each product. Figure 12 shows the relationship between the damage rate index and fracture energy. The damage rate index has a weak correlation with high-temperature flexural strength, but it decreases linearly as the fracture energy increases. Therefore, it can be concluded that for damage in industrial furnaces, controlling crack propagation by increasing fracture toughness is more effective than controlling failure by increasing strength. High fracture toughness magnesia-carbon bricks are suitable for use in converter charging walls.

To clarify the main causes of damage to the converter charging furnace walls, scrap steel drop impact tests were conducted. Based on the test results, the primary cause of the damage was identified as the initiation and propagation of cracks due to scrap steel impact, as well as the connection of these cracks leading to breakage. Subsequently, high-strength magnesia-carbon bricks that inhibit crack initiation and high-fracture-toughness bricks that inhibit crack propagation were developed. Evaluation results from use in industrial furnaces showed that the high-fracture-toughness magnesia-carbon bricks performed well and effectively controlled crack propagation.