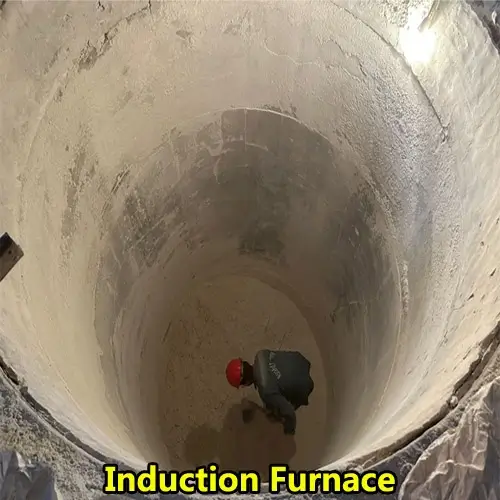

Silica Ramming Mass is used in the lining of induction furnaces. Better quality of Refractory lining results in the smooth working of furnaces, optimum output and better metallurgical control. Refractory means it can withstand very high temperatures without melting or breaking. Ramming mass forms a protective layer inside the furnace. This layer keeps the heat from damaging the furnace walls and helps maintain a steady temperature.

Silica ramming mass is made from two main ingredients: silica and a bonding agent. Silica is a type of sand that’s really good at handling heat. The bonding agent helps hold the silica particles together. These ingredients are mixed, and then the mixture is packed into the furnace lining.

Silica Ramming Mass is an acidic substance which is used for the making of lining in the furnace. Silica ramming mass is made of high purity microcrystalline quartz sand, powder, adding high temperature sintering flux and mineralizes. The Premixed Silica Ramming Mass with Boron Oxide is very effective and useful. Silica ramming mass can safely be used up to an operating temperature of 1600 deg C. Since it expands very little, it is superior to both alumina and magnesia refractories to resist thermal shocks.

Silica Ramming Mass advantages

1. Easy Installation

2. High Heat Resistance

3. Erosion Resistance

4. Thermal Stability

5. Minimal Contamination

6. Improved Furnace Performance

Where is Silica Ramming Mass Used?

1. Steel Industry

2. Glass Industry

3. Foundries

4. Ceramics Industry

Reviews

There are no reviews yet.