About us

Email us

- sales1@wanhaorefractory.com

About Wanhao Refractory

We Are Leading International Factory In The World

Luoyang Wanhao New Material Co., Ltd. is situated 10 kilometers south of Luoyang which is an ancient city of thirteen dynasties. Luoyang is of rich refractory raw materials and convenient transportation which contribute a lot to Wanhao’s production and development.

Wanhao has a staff scale of 157 people including 37 engineers as well as 180 sets of production and test devices, and also Wanhao has an annual output of 160,000 tons of refractory products. Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractories for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc. With strong technical ability, advanced technology and equipment, Wanhao has established technical cooperation relationship with some refractory research institutions and universities, including Luoyang Institute of Refractory Research, Wuhan University of Science and Technology and Beijing University of Science and Technology.

Due to Wanhao’s design and research ability, continuous production and strict quality management, it has established long and stable cooperation relationship with many steel plants from Hunan, Jiangsu, Guangdong, Guangxi, Hebei, Yunnan Province; except for domestic clients, Wanhao is also trying best to develop foreign markets, Wanhao’s refractory products have been exported to more than 20 countries till 2023, such as Canada, India, South Korea, Malaysia, Thailand, Bangladesh, Saudi Arabia, UAE, Iraq, Pakistan, Philippines, Vietnam, Singapore, Tajikistan, Indonesia. Besides, Wanhao magnesia carbon brick and alumina magnesia carbon brick are praised for “Famous Brand Product of Henan”, and Wanhao has won fames such as “AAA Grade Enterprise for Quality, Reputation and Service of China” and “Trustworthy Enterprise”.

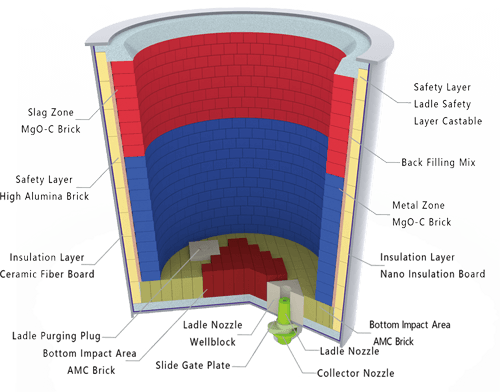

Ladle furnace

The ladle furnace (LF) makes it possible to divide the steel melting operations, carried out in EAF, from those of treatment and refining. The liquid steel produced by the EAF is poured into the ladle, which serves as a reactor for metallurgical operations at the treatment stations.

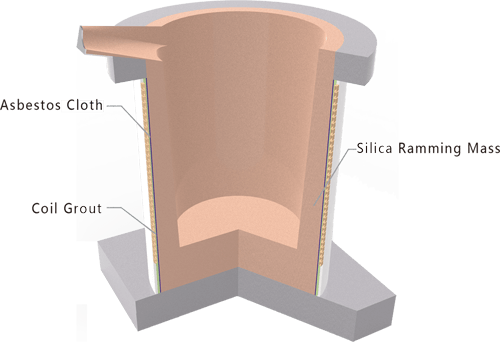

Induction furnace

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. Induction furnace capacities range from less than one kilogram to one hundred tons, and are used to melt iron and steel, copper, aluminum, and precious metals.

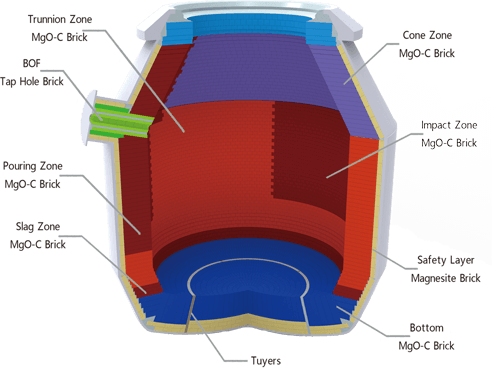

BOF furnace

The basic oxygen furnace (BOF) is a vessel used to convert pig iron, of about 94 percent iron and 6 percent combined impurities such as carbon, manganese, and silicon, into steel with as little as 1 percent combined impurities.

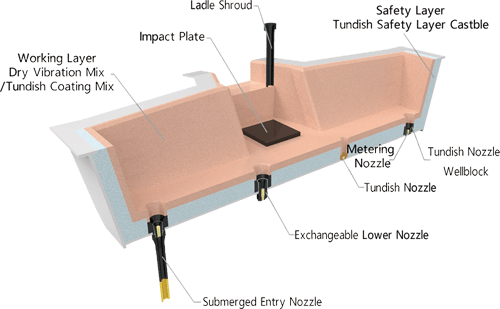

Tundish Furnaces

Tundish Furnaces are well suited for applications that require multiple alloy flexibility and when hot metal is readily available. Tundish Automated Pouring Furnaces use a refractory-lined tundish fitted with a stopper rod pouring mechanism that make them ideal for applications needing quick alloy changes of gray, malleable and treated ductile iron.

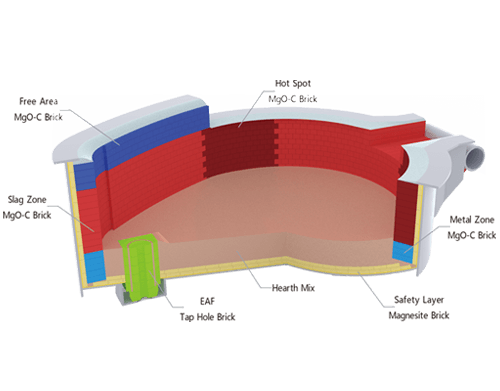

Electric arc furnace

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc, combined with the action of chemical power provided by the use of oxygen and fuel. In electric arc furnaces, the charged material is directly exposed to an electric arc, and current from the furnace electrodes passes through the charged material.

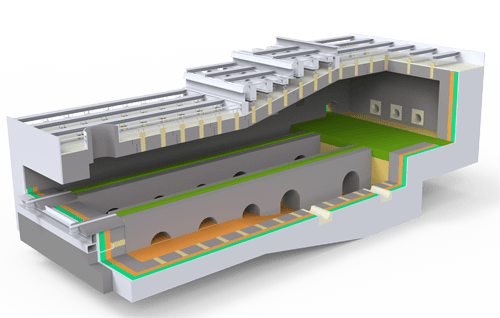

Reheating Furnaces

Reheating Furnaces serve the purpose of heating steel blooms, billets or slabs in steel rolling mills. Reheating furnaces takes this steel stock up to approximately 1200 degree Celsius. The steel begins to deform at this temperature, and the steel rolling process can begin.

Quick Service On Emergency Call - 24/7

Need product sample or Free technical guidance? Get your answer within 24 hours.

- +8615225115555