Factors affecting the service life of converter tapping nozzles were addressed by modifying the nozzle seat bricks and sleeve bricks, improving the nozzle assembly process, optimizing the nozzle replacement procedure, and enhancing the material quality of the nozzle sleeve bricks. Concurrently, measures such as reducing the iron oxide content in slag and enhancing slag retention techniques were implemented to mitigate erosion during operation. Following these interventions, the tapping nozzle lifespan increased from 200 to 370 furnaces. This resulted in an annual reduction of 23 nozzle replacements per furnace and minimized downtime by 2,070 minutes per furnace.

The tapping hole serves as the essential passage for molten steel to exit the converter at the end of the process. Typically composed of the tapping hole seat brick and sleeve brick, it is one of the critical refractory components in the converter. Due to the high volume of molten steel flowing through the tapping hole, it is subjected to dissolution, erosion, and oxidation-melting damage from high-temperature solutions (molten steel and slag). Consequently, the tapping hole experiences severe erosion during operation, resulting in a short service life. Maanshan Iron and Steel Co., Ltd.’s First Rolling Mill Plant extended the service life of taphole lining bricks from 138 to 182 furnaces by implementing measures including: upgrading the material of the taphole sleeve bricks, enlarging the taphole inner diameter, performing periodic spray repairs on the taphole inner surface, and installing a lower sleeve during the later stages of taphole use. Shanxi Jinyue Iron & Steel Company’s steelmaking plant enhanced the average life of tapping nozzles from 130 to 491 taps by improving nozzle material and packing quality, optimizing daily maintenance, and other measures. Shandong Shiheng Special Steel Company optimized its taphole through measures including refining the assembly process, optimizing the replacement procedure, and adjusting slag retention techniques. This resulted in a significant increase in taphole service life from 200-300 furnaces before implementation to 700-800 furnaces. Building upon industry best practices, our research team analyzed issues with ladle nozzles at Laiwu Branch of Shandong Iron and Steel Group (hereafter Laiwu Steel) and implemented targeted modifications. These improvements significantly extended the service life and operational efficiency of the ladle nozzles.

1.Problems exist at the converter tapping outlet

The existing tapping hole presents four key risks during operation. First, its service life is short. With an average lifespan of approximately 200 ladle operations, each converter requires tapping hole replacement every six days on average. Second, high risk of molten steel penetration. The primary brick of the taphole is connected to the inner nozzle of the slide plate using refractory mortar. During tapping, molten steel can seep through the mortar joints, leading to penetration accidents at the inner nozzle. Third, lengthy operation time. Replacing a taphole takes an average of 90 minutes. If replacement is necessitated by internal nozzle leakage, the process extends by approximately 60 minutes due to the required cleanup of solidified molten steel, severely impacting production output. Fourth, high labor intensity. Operating conditions significantly increase the physical demands on workers during taphole replacement. Should internal nozzle leakage occur, the subsequent task of burning off solidified molten steel further elevates both the workload and the inherent risks for on-site personnel.

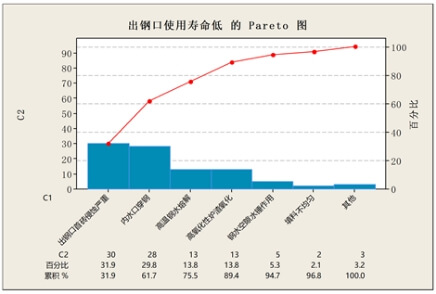

2.Analysis of the causes for short ifespan of ladle tipping spouts

2.1. Oxidation of Furnace Gas

From the moment the molten iron is charged into the converter to the blowing process, the tapping outlet is in a high-temperature oxidizing atmosphere. The furnace gas generated during the blowing process contains a large amount of CO. When it is discharged from the tapping outlet, a C-O reaction occurs, forming a decarburized layer on the inner wall surface of the tapping outlet, which directly causes damage to the tapping outlet.

2.2. Frictional damage and mechanical erosion caused by molten steel and slag

During tapping, the tapping spout must withstand the enormous pressure of the molten steel inside the converter. At the same time, as the molten steel and slag flow out of the tapping spout, they rub against and scour the inner wall of the tapping spout, directly causing mechanical damage to the inner wall of the tapping spout.

2.3. High-Temperature Melting of Molten Steel and Slag

The tapping temperature is generally 1640℃. Under the action of high-temperature molten steel, the material at the tapping point will soften, its strength will be significantly reduced, and it may even melt, causing damage to the tapping point.

2.4. Chemical Erosion of Molten Steel and Slag

The physical and chemical properties of the tapping outlet are shown in Table 1.

When the molten steel is tapped at the end of the converter smelting process, it generally has a strong oxidizing property, especially the slag. Under high temperature and high oxidizing conditions, the following chemical reactions will occur.

[C]+[O]=CO( g )

(MgO)+[C]=Mg(g)+CO( g )

During the chemical reaction, oxygen in the molten steel or slag can extract carbon from the magnesia-based taphole material, resulting in a porous refractory structure and reduced strength. Additionally, if the slag basicity is too low or the MgO content in the slag is low, the following chemical reactions will occur.

(SiO2)+[C]=SiO(g)+CO( g )

This will also exacerbate chemical corrosion at the tapping point.

3.Measures to address the short lifespan of the converter taphole

3.1. Optimization of steel tapping outlet

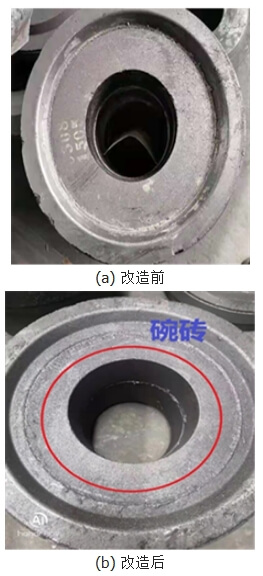

Based on theoretical analysis, inspection of the tapping spout revealed that the most severely corroded area was the first brick section. Severe corrosion of the first brick was the primary cause of the tapping spout replacement, as shown in Figure 1. The inner nozzle brick and the tapping spout first brick were connected by manually applying refractory mortar, inevitably creating gaps between them. During tapping, the static pressure of the molten steel allowed steel to easily penetrate these gaps, leading to severe corrosion. Since the first brick section and the tapping spout are a single unit, severe corrosion of the first brick necessitates replacing the entire tapping spout.

The first brick of the steel outlet is modified into a separate unit. A bowl-shaped step is added between the first brick and the inner water inlet to prevent direct contact between the inner water inlet and the first brick of the steel outlet, as shown in Figure 2. After the steel outlet has been used a certain number of times, the inner wall of the bowl brick will be corroded, at which point the bowl brick can be replaced directly.

3.2. Reduce the ∑FeO% content in the final slag of the converter to minimize erosion and scouring at the taphole

Factors such as inappropriate timing of TSC measurement, manual intervention instead of using an automated steelmaking model, and using the same operating model for different scrap ratios led to insufficient lance pressing time at the endpoint and excessively high lance positions during the process, resulting in slag foaming at the endpoint. A new lance position model needs to be developed to ensure sufficient lance pressing time at the endpoint, reduce human intervention, and guarantee the utilization rate of automated steelmaking.

Currently, the oxygen lance uses a throat diameter of 35.2 mm, with a designed working oxygen pressure range of 0.85~0.95 MPa. In the process control of low scrap ratio smelting furnaces, a lower oxygen pressure and lower lance position operation mode is typically adopted to ensure sufficient slag formation while suppressing splashing. The normal operating oxygen pressure is controlled within the range of 0.85~0.90 MPa. In high scrap ratio smelting, a low lance position is detrimental to converter slag formation, and a low oxygen pressure is detrimental to converter molten pool temperature increase. Increasing the converter oxygen supply pressure to above 0.90 MPa, and improving the converter molten pool temperature through high oxygen supply intensity smelting, can ensure rapid melting of the scrap steel in the furnace. The high scrap steel ratio extends the initial high-lance position in smelting to approximately 5 minutes. This high-lance position increases the ferrous oxide content in the slag, ensuring thorough slag melting and improving the initial slag dephosphorization rate. The large scrap steel volume also extends the converter slag opening time from the original 4 minutes to 6-7 minutes. After slag opening, the oxygen lance is gradually moved to the normal position until the end point. The final lance pressing time is guaranteed to be greater than 1.5 minutes.

Through these measures, the ∑FeO% content in the slag is reduced from 20% to 16%, decreasing the slag’s oxidizing properties. This reduces corrosion to the taphole, increasing its lifespan, and also reduces iron loss and steel consumption, bringing dual benefits to the converter.

4.Effect Analysis

4.1. Improved service life of the tapping spout

After the project was implemented, the average service life of the tapping spout increased from an average of 200 heats to an average of about 370 heats, reducing the number of times the tapping spout needed to be replaced.

The lifespan of a tapping outlet is the number of heats that can be produced from the tapping outlet to the tapping outlet.

4.2. Shorten the changeover time of the steel tapping equipment and reduce the production cycle

After modifying the taphole first brick into a separate unit and reducing the iron oxide content in the slag, the average service life was increased by more than 170 heats, which is more than 50 heats longer than the average service life of tapholes in similar converters in China. At the same time, the number of taphole replacements was significantly reduced, improving production efficiency. Specifically, before the improvement, the taphole had to be replaced every 200 heats; after the improvement, it has to be replaced every 370 heats. Assuming 10,000 heats per converter per year, this reduces the number of taphole replacements by 23 per furnace per year. Replacing a taphole takes an average of about 90 minutes, resulting in a reduction of 2070 minutes of production time per furnace per year.

4.3. Shorten steel tapping time and reduce production cycle

Throughout the entire lifespan of the tapping spout, using the replaced tapping spout reduced the tapping time from an average of 4 minutes and 40 seconds to an average of 4 minutes.

The tapping time is the time required for all the molten steel to be poured from the converter into the ladle.

4.4. Reduce process temperature drop and decrease refining power consumption

After the tapping time was reduced from an average of 4 minutes and 40 seconds to an average of 4 minutes, the process temperature drop (temperature drop from converter tapping to refining station entry) decreased from an average of 95.6℃ to an average of 82.3℃, thus reducing refining power consumption.

Based on the actual monthly power consumption of Refining Unit 1 (data source: process power consumption statistics table of our plant’s mechanical equipment department), Table 4 compares the monthly power consumption of Refining Unit 1 in 2021. In Table 4, data from January to March are before the tapping outlet modification, and data from April to December are after the modification. The actual reduction in refining power consumption after the project implementation is: 34.48 − 29.37 = 5.11 kWh/(t∙steel).

In summary, the technology of splitting the first brick at the tapping spout effectively solves many problems that arise during use. Through the research and application of the split design modification of the first brick, the first brick can be replaced separately when the tapping spout is severely eroded, greatly improving the operating rate, significantly reducing labor intensity, and ensuring the personal safety of employees. It has broad promotion value and application prospects in the tapping spouts of similar converters.

5.Conclusion

1) The first brick at the converter taphole was modified into a separate unit, with a bowl-shaped step added between the first brick and the inner nozzle;

2) To reduce slag erosion of the taphole, the smelting process was optimized, reducing the ∑FeO% content in the slag from 20% to 16%;

3) The service life of the taphole increased from an average of 200 heats to an average of 370 heats. Replacing the taphole only takes 3-5 minutes, saving 2070 minutes per heat per year; the temperature drop during tapping (converter tapping – refining station entry) decreased from an average of 95.6℃ to an average of 82.3℃, and the refining furnace power consumption decreased by 5.11 kWh/(t∙steel).