The new technologies and processes required for producing high-value-added specialty steels also impose higher demands on the service life of ladle refractories. At Benxi Steel’s Plate Rolling Mill, the output of pipeline steel, rectangular billets, and other deeply desulfurized steels refined via the LF route have increased annually. Furthermore, following the completion of ladle dual-vent brick upgrades in 2011, heightened argon blowing intensity has intensified slag agitation at the ladle slag line, causing significant damage to magnesium-carbon bricks. This has shortened the service life of slag line bricks and severely contributed to slag line leakage. Therefore, extending the service life of ladle slag line bricks and reducing steel leakage at the slag line has become a key research focus for engineering technicians.

1.Production Status

The Benxi Steel Plate Rolling Mill currently operates seven continuous casting machines: – Two 1600mm thick slab machines (dual-stream) – Two 1700mm thin slab machines (single-stream) – One 350mm x 470mm rectangular billet machine (four-stream) – One 1900mm wide slab machine (dual-stream) – One 2200mm wide slab machine (single-stream) (single-strand). There are 11 refining treatment stations: 5 LF refining furnaces, 5 RH vacuum refining furnaces, and 1 AHF chemical heating furnace.

The primary process routes are BOF-LF-CCM, BOF-RH-CCM, BOF-AHF-CCM, BOF-LF-RH-CCM, or BOF-RH-LF-CCM.

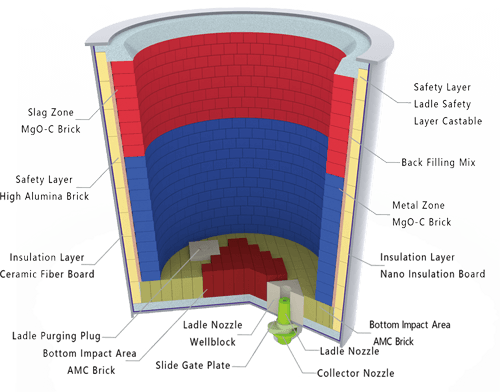

The steelworks currently operates 65 180-ton ladles with Mg-C refractory bricks forming a 160mm slag line. Since RH and AHF refining stations exhibit minimal erosion at the ladle slag line, this discussion focuses on the impact of erosion at the LF refining furnace slag line.

2.Erosion Mechanism of Mg-C Bricks

LF furnace refining slag primarily consists of oxides of Ca, Si, Al, Mg, Mn, and Fe at a certain alkalinity. Mg-C bricks react with high-temperature LF refining slag to form calcium-magnesium olivine, wherein calcium oxide, silicon dioxide, and a portion of magnesium oxide originate from the molten slag.

The reaction is as follows:

Calcium-magnesium olivine has a low melting point and low viscosity at high temperatures, making it prone to flow into the slag during slag agitation. On the other hand, graphite in magnesium-carbon materials can be oxidized by oxides in the slag or even dissolve directly into the molten steel it contacts.

(FeO)slag+C(s)→Fe(l)+CO(g)

(MnO)slag+C(s)→Mn(l)+CO(g)

Graphite oxidizes into CO(g), leaving pores at the original site that serve as pathways for molten slag to penetrate into the refractory material. The integrity of Mg-C bricks is compromised, isolating magnesia particles that subsequently flow into the molten slag, causing erosion of the refractory material. Impurities like silicon and calcium in magnesia raw materials can also form low-melting-point peridotite phases at high temperatures, which similarly serve as pathways for slag intrusion into the refractory material.

During actual smelting operations, graphite within magnesia-carbon bricks located at the slag-molten steel interface can dissolve into the molten steel. This structural damage to the bricks is a significant factor that cannot be overlooked.

3.Factors Affecting the Erosion of Mg-C Bricks

The slag line is the most severely stressed area of a ladle’s refractory lining. In actual production, erosion at the ladle’s slag line is influenced by factors such as refractory quality, lining construction quality, and smelting conditions. When these influencing factors change, abnormal erosion may occur at the ladle’s slag line, potentially leading to slag line leakage.

3.1 Impact of Refractory Quality

The erosion resistance, high-temperature strength, and thermal shock resistance of Mg-C bricks are influenced by factors such as raw material quality, the particle distribution of magnesia and graphite, and the addition of additives. Unreasonable particle size distribution of magnesia and graphite, coupled with improper additive formulation, causes significant expansion of Mg-C bricks during high-temperature operation. This generates excessive thermal stress, degrading thermal shock resistance. Consequently, vulnerable areas like slag line junctions and brick joints erode rapidly, forming “bun-shaped erosion.” Figure 1 shows severe “bun-shaped erosion” at the slag line of ladle No. 35 in Benxi Steel’s steelmaking plant, resulting in molten steel leakage.

3.2 Impact of Masonry Techniques on Abnormal Erosion of the Bu Line

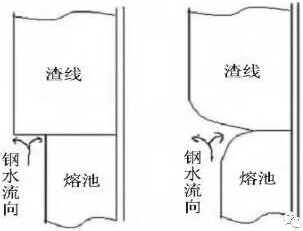

During minor repairs to the ladle slag line, a significant step difference of up to 50mm formed between the new slag line and the existing joint. During argon blowing and stirring in the refining process, vortices formed at the step-off location accelerated erosion at this point, resulting in pronounced pitting. The depth of the pits at the bottom could reach up to 70mm relative to the brick working surface. Such step-offs can also occur if the mortar between the working layer and permanent layer is not thoroughly cleaned during bricklaying. Step-offs in the slag line bricks lead to abnormal slag line erosion.

3.3 Effect of Smelting Conditions on Slag Line Erosion

To meet the temperature and composition requirements of steel grades, the refining LF furnace requires electrode heating. The slag temperature in the arc zone can reach 2000°C and remains at high temperatures for extended periods. Under argon agitation, the slag exhibits strong erosion of the slag line due to its high basicity and low viscosity. Typically, the slag line erosion rate remains below 3.0 mm per treatment. Table 2 shows the erosion rate reaching 4.0 mm per treatment for the slag line of a specific vessel in Tank No. 36 after 22 LF furnace treatments (without other refining processes).

Due to the large production volume of special steel grades, strict requirements are imposed on ladle condition, prohibiting the presence of “foreheads” or “inner bulges” along the ladle rim. Benxi Steel’s steelmaking plant employs slag hooking methods and specialized hooking equipment. During the process of hooking ‘forehead’ slag and “inner bulge” slag, the slag line bricks themselves are highly susceptible to damage, resulting in pitting or fractures. If the damaged slag line brick body is not promptly reported for repair or remains undetected due to slag coverage during subsequent use, it can lead to slag line leakage accidents during LF furnace heating. Figure 3 shows a No. 32 ladle whose slag line body was damaged during a particular ladle cycle. However, due to an operator’s misjudgment, the ladle was reused, resulting in a slag line leakage accident during LF furnace processing.

4.Conclusion

1. Factors such as raw material quality, magnesia and graphite particle distribution, and additive incorporation affect the quality of Mg-C slag line bricks, thereby influencing their erosion.

2. Misalignment during ladle lining accelerates erosion of Mg-C slag line bricks.

3. Erosion of Mg-C bricks used in LF refining slagging processes increases sharply, with phenomena like “forehead slag” and “internal expansion slag” causing damage to the brick body.