Magnesia carbon bricks are a new type of refractory material that emerged in the 1970s. Made from high-temperature sintered or fused magnesia and carbon, and using various carbon binders, these unfired refractory materials retain the advantages of carbon-based refractories while overcoming the inherent shortcomings of alkaline refractories, such as poor spalling resistance and slag absorption.

To this day, magnesia carbon bricks are still widely used in the steel and metallurgical industry. Their application has improved various technical and economic indicators of converters and reduced refractory consumption. Furthermore, as an unfired product, magnesia carbon bricks save at least 80% in fuel production compared to traditional fired magnesia dolomite bricks.

Properties of magnesia carbon bricks

Magnesia carbon bricks, made of magnesium oxide and carbon, both of which have high melting points and are insoluble in each other, offer high melting resistance.

Magnesia carbon bricks are a composite structure, primarily composed of magnesium oxide clinker, which exhibits strong resistance to alkaline slag, and carbon, which has poor wettability with molten slag. This gives them excellent slag resistance. In particular, they offer strong resistance to slag penetration, resulting in a much shallower penetration layer than older fired alkaline bricks.

Dry graphite possesses excellent thermal shock resistance, and thus, inheriting its excellent properties, magnesium carbon bricks possess high thermal conductivity, a relatively low linear expansion coefficient and elastic modulus, and high high-temperature strength, essentially preventing structural damage and spalling caused by cracking during use.

In addition to these excellent properties, magnesium carbon bricks also exhibit excellent thermal creep resistance, demonstrating exceptionally good creep resistance compared to other ceramic-bonded bricks.

Application of magnesia carbon bricks in converter steelmaking

Since the advent of the oxygen converter, furnace lining materials have undergone three evolutionary stages: tar-coated dolomite bricks—calcined alkaline oil-impregnated bricks—magnesium-carbon bricks. Since the 1980s, significant advancements have been made in steelmaking converters and their refractory linings. Steelmaking converters have completed their transition toward larger scales and automation. Current developments are focused on dual-blowing systems and higher operating temperatures.

During smelting operations, operating conditions and wear patterns vary significantly across different sections of the converter. Consequently, distinct refractory materials are selected for each section based on its specific operational demands.

(1) Furnace Opening: Subject to extreme temperature fluctuations, severe erosion from molten slag and high-temperature exhaust gases, and impact during scrap removal and charging operations, the refractory materials for the furnace opening must exhibit high thermal shock resistance and slag resistance. They must withstand erosion from molten slag and high-temperature exhaust gases, resist steel adhesion, and facilitate easy cleaning.

(2) Furnace Cap: The furnace cap experiences severe slag erosion, coupled with temperature fluctuations, carbon oxidation, and erosion from dust-laden exhaust gases. Therefore, magnesium-carbon bricks with strong slag resistance and thermal shock resistance are required.

(3) Charging Side: During blowing, splashes of slag and molten steel can cause chemical corrosion, wear, and erosion on the charging side. Additionally, the charging side endures direct impact and erosion from scrap steel and molten iron, causing severe mechanical damage. Consequently, magnesium-carbon bricks must possess not only high slag resistance and substantial high-temperature strength but also excellent thermal shock resistance. High-strength magnesium-carbon bricks with added oxidation inhibitors are typically employed.

(4) Tapping Side: The tapping side is largely unaffected by mechanical damage during charging and experiences minimal thermal shock impact. However, it is subjected to thermal shock and erosion from molten steel during tapping, though at a significantly slower rate than the charging side. When using the same material as the charging side, a thinner construction is employed to maintain balanced lining life across the converter.

(5) Slag Line Area: The slag line is the area where the lining is severely eroded by prolonged contact with molten slag. On the tapping side, slag erosion is less pronounced due to the shifting slag position during tapping. On the slag removal side, however, severe erosion occurs due to intense slag attack combined with additional stresses from the furnace belly during blowing operations. Therefore, magnesia-carbon bricks with excellent slag resistance are required for this area.

(6) Trunnion sides: Beyond damage during blowing, these areas lack protective coatings and are difficult to repair. Carbon oxidation in the lining material causes severe deterioration. High-grade magnesia-carbon bricks with superior slag resistance and oxidation resistance should be used.

(7) Furnace bottom and hearth: These areas endure intense molten steel erosion during blowing but generally suffer less damage than other sections. Low-carbon magnesia-carbon bricks or tar-impregnated dolomite bricks may be used. When employing high-speed blowing with a shallow melt pool, severe damage may occur at the center of the furnace bottom. Additionally, bottom-blowing operations may exacerbate damage in these areas, necessitating the same brick material used on the charging side of the furnace belly.

Currently, comprehensive bricklaying is widely adopted to enhance the technical and economic performance of converters.

Use of magnesia carbon bricks in electric furnaces

Currently, electric furnace walls are almost entirely constructed using magnesia-carbon bricks. Consequently, the lifespan of these bricks determines the operational life of the furnace. Key factors influencing the quality of magnesia-carbon bricks for electric furnaces include: The purity, crystallinity, and flake size of flake graphite, which serves as the carbon introduction source; Thermosetting phenolic resin is typically selected as the binder, with the primary influencing factors being the addition amount and residual carbon content. It has been demonstrated that adding antioxidants to magnesia-carbon bricks can alter and improve their matrix structure. However, under normal operating conditions of electric furnaces, antioxidants are not essential components of these bricks. Only in arc furnaces handling high-FeO slag—such as those using direct reduced iron, areas with irregular oxidation, or hot spots within the furnace—does the addition of various metallic antioxidants become a critical component of the magnesia-carbon brick formulation.

The erosion behavior of magnesium-carbon bricks at the slag line manifests as the formation of a distinct reaction-compacted layer and a decarburized porous layer. The reaction-compacted zone, also termed the slag penetration zone, represents the erosion area where high-temperature liquid slag infiltrates the brick interior after decarburization creates numerous pores. Within this zone, FeO in the slag is reduced to metallic iron. Even Fe₂O₃ dissolved in MgO and intergranular Fe₂O₃ phases are reduced to metallic iron. The penetration depth of molten slag into the brick primarily depends on the thickness of the decarburized porous layer, typically terminating at residual graphite. Under normal conditions, the decarburized layer in magnesium carbon bricks remains relatively thin due to the presence of graphite.

Electric furnace tapping ports employ either tilting ladle tapping or bottom tapping methods. When tilting ladle tapping is used, magnesium-carbon bricks are rarely selected; instead, Al₂O₃-based or ZrO₂-based bricks are chosen, supplemented with non-oxygen-containing elements like C, SiC, and Si₃N₄. For bottom tapping, the tapping outlet comprises an outer sleeve brick and an inner tube brick. Magnesium-carbon tube bricks are used for the bottom tapping outlet, with the tube diameter determined by factors such as furnace capacity and tapping time, typically ranging from 140 to 260 mm in inner diameter.

A steel mill’s electric furnace achieved preliminary success by replacing sintered magnesia bricks with medium-grade and low-grade magnesia-carbon bricks in the steel tapping outlet and copper tapping outlet side areas. This extended furnace life from approximately 60 ladles to over double that duration. Post-use inspection revealed the magnesia-carbon bricks at the slag line remained largely intact without slag adhesion. The slag line area required no furnace repairs, thereby reducing labor intensity while enhancing molten steel purity and production efficiency.

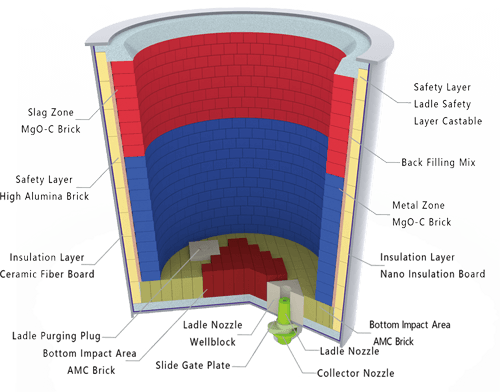

The use of aluminum-magnesium-carbon bricks in ladle

MgO-C bricks are primarily used in the ladle furnace and ladles for refining, primarily in areas such as the headroom and slag line. Operating conditions dictate that these areas require refractory materials with excellent resistance to high temperatures, thermal shock, and mechanical damage caused by slag erosion. Magnesia-chromium refractories were previously used in these areas, but due to environmental concerns about chromium, their use has decreased. Magnesia-carbon bricks are now preferred.

Due to the severe damage to MgO-C bricks in new ladles during the preheating process, a loose, decarburized layer can reach 30-60mm thick. This layer is washed away during the injection of molten steel, introducing magnesia grit into the slag. Preventing carbon from burning off during preheating is crucial for increasing the service life of MgO-C bricks in the ladle headroom and slag line. The technical measures include adding composite antioxidants to the magnesia carbon bricks. The key is to cover the surface of the magnesia carbon bricks with alkali-containing low-melting glass phase liquid after lining to protect the carbon in the magnesia carbon bricks from being burned during the preheating process of the ladle.