Air bricks are crucial functional components in the bottom-blown argon process for ladle secondary refining. They perform the metallurgical functions of both homogenizing and purifying molten steel. On the one hand, the argon gas agitation ensures uniform temperature and composition across the molten steel within the ladle. Furthermore, through the vacuum pump principle, argon bubbles adsorb fine non-metallic inclusions such as Al₂O₃, SiO₂, and MA on their surfaces, while their interiors draw harmful gases such as nitrogen, hydrogen, and oxygen from the molten steel. As the bubbles rise, they gradually converge and grow, ultimately being captured by the slag layer. Therefore, air bricks are essential refractory materials for clean steelmaking, and their service performance directly impacts the purity of the molten steel. Furthermore, the service life of air bricks is a bottleneck limiting the lifespan of ladle minor repairs, and their stable service life is a prerequisite for smooth ladle production. To this end, this article briefly reviews the material evolution and structural evolution of ladle air bricks. The structural characteristics and metallurgical functions of three types of composite air bricks—dispersion-type, core-plate-type, and ceramic-tube-type—are analyzed, with a focus on the damage mechanisms of composite air bricks.

1.Structural evolution of breathable bricks

1.1 Single structure breathable brick

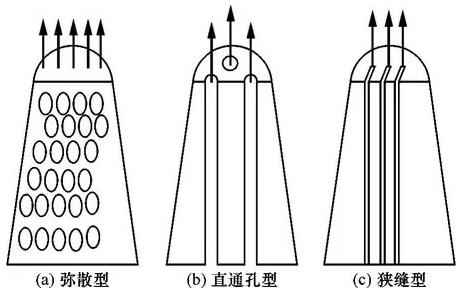

In the 1960s, the first diffused air brick was invented. It reversed the theory of close packing of particles, used a large number of equal-sized particles, and introduced ablative materials to cleverly prefabricate a large number of non-directional through-holes [1]. The brick body was formed by hydraulic or vibration pressure. Due to the constraints of the molding method, the height generally did not exceed 270 mm [2]. Because the high-aluminum or magnesium diffused air bricks have poor anti-scouring performance and are limited in height, they cannot meet the service life requirements. In the 1980s, straight-through hole air bricks came into being. Several stainless steel pipes with a diameter of 1 to 3 mm were embedded in the bricks, and the brick body was cast and formed. Its service life is longer than that of the diffused type. In the 1990s, following the trend of amorphous refractory products, ultrafine powders and high-efficiency dispersants were introduced, and low-cement chrome corundum castables showed better performance. Straight-through hole-type air bricks gradually decreased in the application of bottom-blown argon ladle, and were eventually replaced by slit-type air bricks made of corundum-spinel or chrome corundum castables. The slits were constructed by high-temperature ablation of polyester film sheets with a thickness of 0.15 to 0.25 mm [3]. Air bricks with single airway structures such as dispersed type, straight-through hole type, and slit type (see Figure 1 for a schematic diagram) are difficult to be widely used in various smelting conditions. In particular, traditional dispersed type and straight-through hole type have been eliminated from the ladle air brick market. In practical applications, single-structure breathable bricks often expose defects that are difficult to overcome [3-6]: high-temperature fired narrow-slit breathable bricks have poor thermal shock resistance, and thermal stress is concentrated within 50 mm from the working surface. When subjected to frequent rapid cooling and heating shocks, longitudinal and transverse cracks are easily generated. After the molten steel penetrates the narrow slits and cross sections, the flow rate decreases or even becomes airtight; traditional dispersion-type breathable bricks have low density, poor resistance to erosion and wear by molten steel, poor resistance to oxygen cleaning, and a short service life. In addition, traditional dispersion-type bricks formed in one piece cannot be designed with safety alarm devices.

1.2 Composite structure breathable bricks

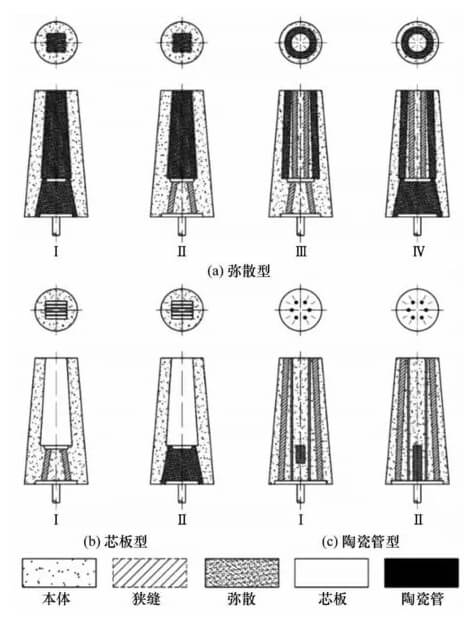

The composite structure of the airway can make the advantages of different structures of air bricks complement each other and make the best use of their strengths and avoid their weaknesses. Currently, several composite structure air bricks with relatively high technical maturity on the market can be divided into three categories according to the main airway structure type: dispersion type, core plate type, and ceramic tube type. Differentiated market demand has prompted the development of single structure air bricks towards composite structure [7]. Dispersion type composite structure air bricks are very popular in steel mills in Japan, South Korea, Vietnam, etc. Core plate type composite air bricks are more popular in steel mills in Europe, the United States and the Middle East, and ceramic tube type composite air bricks are widely praised in steel mills in Russia and other countries. The three types of composite structure air bricks all have usage characteristics that cannot be matched by single structure air bricks: 1) The diameter of bubbles blown out by the diffuse composite structure air brick is smaller than that of the slit type air brick. Under the same flow rate, the number of bubbles is greater, the probability of collision with non-metallic inclusions and harmful gases is significantly increased, and the efficiency of adsorbing small inclusions and absorbing harmful gases is improved [8-9], which is the preferred solution for smelting high-quality clean steel; 2) Due to the existence of energy release space when the plate-like core plate is spliced and the low expansion rate of the corundum-mullite material, the core plate type air brick has excellent thermal shock resistance, thus avoiding the fatal defect of transverse fracture and steel penetration of the high-temperature fired slit air brick, ensuring the high blowing rate of the air brick [5]; 3) The ceramic tube type composite structure air brick has both the high flow rate characteristics of the slit and the small-diameter bubbles that go straight through the micropores. The oxygen cleaning intensity and frequency of the three composite structure breathable bricks are much lower than those of traditional high-temperature fired narrow-slit breathable bricks. During oxygen cleaning, workers are exposed to harsh operating conditions, with high levels of smoke and dust, and significant environmental pollution. With labor costs rising year by year and environmental awareness increasing, the advantages of light firing and no firing are becoming increasingly prominent. For the permeability and service life of breathable bricks, oxygen cleaning is a double-edged sword. Cleaning with an oxygen lance can ensure that the permeability of the breathable bricks is restored, but it will inevitably damage the bricks and cause excessive corrosion of the breathable bricks [10-13]. The order of oxygen cleaning resistance of different structural types of breathable bricks is: traditional high-temperature fired narrow-slit breathable bricks > ceramic tube composite breathable bricks > core plate composite breathable bricks > diffused composite breathable bricks. Conversely, the order of oxygen cleaning necessity, oxygen cleaning intensity, and frequency is: traditional high-temperature fired narrow-slit breathable bricks < ceramic tube composite breathable bricks < core plate composite breathable bricks < diffused composite breathable bricks. Of course, if the air brick can be self-opened during the next smelting cycle and the flow rate reaches the set value, it can be omitted from cleaning.

When designing composite structure air bricks, the principle of “functional zoning, leveraging strengths and avoiding weaknesses, and complementary advantages” should be followed. The air duct structure can be composited in both the vertical and horizontal dimensions: 1) Vertically, according to different functional divisions, the working layer and the safety layer of the air brick each have their own responsibilities. The working layer focuses on thermal shock resistance, corrosion resistance, scouring resistance, etc. The safety layer focuses on high temperature identification and sufficient flow supply, while the casting body assumes the function of structural support and fixing the air permeable element [5]. The most suitable air duct structure and refractory material are selected in different parts to maximize the necessary functions, while not pursuing excessive redundant design for secondary functions, fundamentally solving the problem of local excess performance and local insufficient performance of single structure air bricks [14]; 2) Horizontally, a variety of different air duct structures can also be selected in the working layer of the air brick to comprehensively consider the bottom blowing flow rate, bubble number, bubble diameter, anti-seepage performance, etc. Figure 2 shows schematic diagrams of different types of composite-structured air bricks. Based on lifespan and performance requirements, a variety of airway combinations can be derived. As shown in Figure 2, slits are added to the working layers of both the diffuser and ceramic tube types to compensate for the insufficient flow of the diffuser and ceramic tube air permeable elements. However, differences in the number and layout of slits result in varying contributions to flow.

2.Damage mechanism of composite structure breathable bricks

2.1 Dispersed composite structure breathable brick

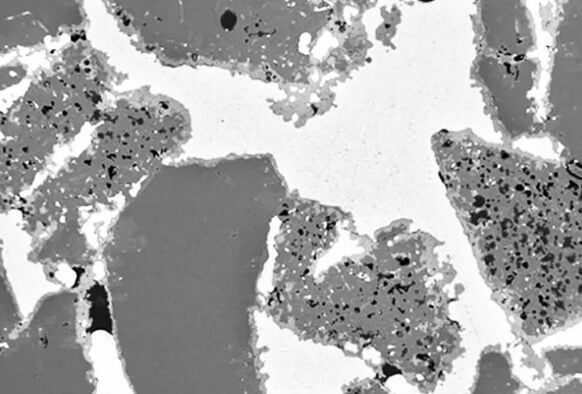

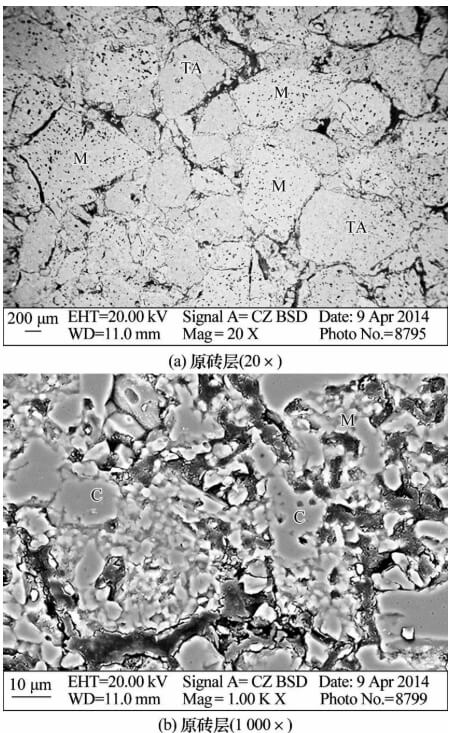

Dispersion-type composite structural air bricks are generally Al2O3-SiO2-Cr2O3-ZrO2 systems, with plate-shaped corundum and white corundum particles (<1 mm) as aggregates, and Al2O3 micropowder, Cr2O3 micropowder, ZrO2 fine powder or zircon fine powder as matrix. Common binders include aluminum dihydrogen phosphate, polyvinyl alcohol, aluminum silica sol, etc. They are formed by isostatic pressing, hydraulic pressure or vibration pressure, and then sintered at a high temperature above 1650℃ [15-24]. When the depth of molten steel penetrating into the dispersion brick is shallow, the residual steel in the through-holes can be blown out by high-pressure back-blowing gas during back-blowing, or when the steel is tapped again, the working layer of the air brick is heated by the molten steel, and the residual steel is melted and blown out by bottom-blown argon gas. When the penetration depth is large, especially after continuous RH refining of multiple furnaces, the residual steel in the through-pores condenses and is difficult to blow out. A high-pressure oxygen lance is inevitably required to purge and remove the permeated layer. Ablation and erosion during oxygen lance cleaning of the permeable brick core are typical causes of damage to dispersed permeable bricks. Figure 3 shows an SEM image of a dispersed permeable brick. It can be seen that molten steel and slag preferentially penetrate larger pores, where they react with the corundum surface. In terms of reactivity, the reaction between slag and tabular corundum is more intense than that of white corundum due to its finer grains and more grain boundaries, as shown in Figures 3(c) and 3(d). Clearly, the primary damage mechanism for dispersed permeable bricks is the penetration of molten steel and slag into the through-pores, rather than erosion of the matrix.

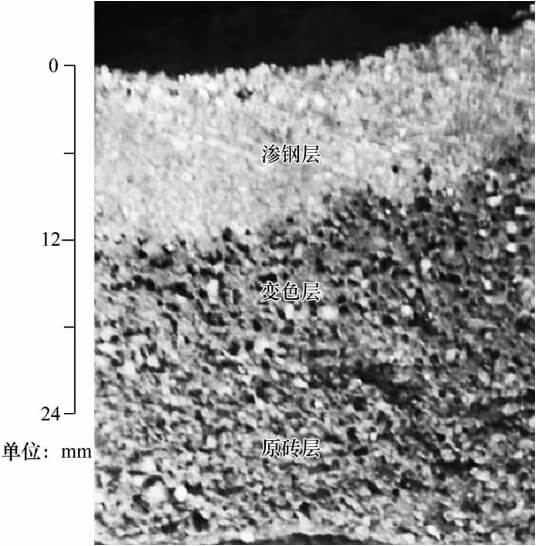

A photo of a dispersed-type remnant brick used in a 300-ton refining ladle at a domestic steel plant. The steel-infiltrated layer is 0 to 12 mm deep from the working surface, with the through-holes blocked by steel, making them completely impermeable. The discoloration layer is 12 to 18 mm deep from the working surface. After each heat of molten steel is poured, the ladle enters the hot repair station and begins backwashing natural gas. This steel-infiltrated layer prevents the backwashed natural gas from contacting air, preventing it from burning. At high temperatures, it cracks and forms a black carbon layer. Therefore, high-pressure flushing and oxygen lance ablation of the permeable bricks during each heat cycle must remove the steel-infiltrated layer to ensure re-blowing in the next heat cycle. Effective ways to extend the service life of dispersed-type composite permeable bricks include optimizing particle size distribution, reducing the proportion of large-diameter through-holes, narrowing the pore size distribution range, and improving the resistance of dispersed bricks to infiltration and penetration by molten steel and slag, minimizing the thickness of the steel-infiltrated layer, and reducing the frequency of oxygen lance cleaning [24-26].

2.2 Core plate type composite structure breathable brick

Figure 5 is a SEM photo of the core plate type residual bricks used in a steel plant. The EDS analysis of each point and layer in Figure 5 is shown in Table 1.

The core plate is mainly made of corundum-mullite. The aggregate is mainly plate-shaped corundum and sintered mullite fine particles (≤1 mm). Due to the inconsistency of the thermal expansion coefficients of the two particles, microcracks are generated around them. The matrix is made of Al2O3 micropowder and SiO2 micropowder. After high-temperature sintering, the mullite generated by the in-situ reaction in the matrix acts as a binding phase, connecting the corundum and mullite particles [5, 27-30]. As can be seen from Figure 5 (c) and Table 1, the bright part (long strips and dots) is the iron-aluminum spinel generated by the reaction of small white corundum particles (1-0.5 mm, 0.5-0.1 mm) with molten steel (see point 1); the gray part is the reaction of small mullite particles, mullite matrix binding phase with CaO in molten steel and slag to form a low-melting-point aluminum-iron-silicon-calcium phase (see point 2), which is easily cleaned away by oxygen during thermal repair. Conventional corundum-mullite core plate and CaO in steel slag easily form a low melting point phase. Cr2O3 and ZrO2 can be introduced into the core plate [30] to improve the core plate’s resistance to erosion by molten steel and steel slag, reduce slag penetration and erosion, or use silicon-free materials such as high-purity chromium corundum and high-purity corundum spinel to avoid the introduction of SiO2 into the core plate without weakening the high-temperature mechanical properties and thermal shock resistance, thereby improving the core plate’s resistance to slag erosion.

2.3 Ceramic tube composite structure breathable brick

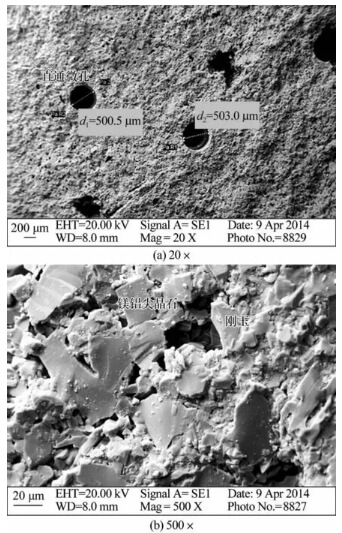

The ceramic tube has a diameter of approximately 15 to 25 mm and contains dozens of straight micropores with diameters of 0.3 to 0.5 mm. An SEM photograph of the ceramic tube-shaped air brick is shown in Figure 6.

Figure 6 shows a highly circular micropore with a diameter of 0.5 mm. The ceramic tube is primarily made of corundum-spinel, using tabular corundum and presynthesized spinel as raw materials. A small amount of soft clay, a plasticizer, and an organic binder are added, and the resulting material is extruded and molded. The process is followed by curing, drying, and high-temperature sintering. A small amount of liquid phase is present in the matrix.

Figure 7 shows a photograph of a remnant of a ceramic tube-shaped brick used in a 180-ton ladle at a foreign steel plant. The surface of the air brick is relatively smooth, free of residual steel and slag. This suggests a transverse fracture in the air brick, which also broke four ceramic tubes. The black ceramic tubes are due to a black appearance. This occurs because the air brick fractures during natural gas backflow, interrupting the air passage. This prevents the backflowing natural gas from coming into contact with the oxygen injected from the oxygen lance, resulting in the high-temperature cracking of the natural gas and the generation of residual carbon.

Therefore, improving the thermal shock resistance of the ceramic tubular breathable brick is the key to solving the damage problem. In addition, if the viscosity of the molten steel is low, it will penetrate into the straight-through micropores under static pressure. When the penetration depth is large, the molten steel condenses, and the cold steel is difficult to blow out during backblowing. If the pore wall’s resistance to molten steel infiltration can be improved, or the pore diameter can be reduced to less than 0.2 mm, the problem of steel seepage through the straight-through micropores can be solved.

The airway structure of a breathable brick determines its permeability, which in turn affects its metallurgical performance and service life. Regardless of the structural type, the key to its production and use lies in the formation and maintenance of the airway (pores, pipes, slits). In addition to the quality of the material, the effectiveness of a breathable brick is also closely related to the airway manufacturing process and operating procedures. For air-permeable bricks with different composite structures, their damage mechanisms and improvement measures are as follows:

(1) Different types of composite air-permeable bricks have different airway structures and materials, and their damage mechanisms are different: after the molten steel and steel slag penetrate into the dispersed air-permeable bricks, the through pores are blocked, and the infiltrated steel layer is washed away and melted or burned by the oxygen gun, which is the main damage mechanism of the dispersed composite air-permeable bricks; CaO in the steel slag reacts with the mullite binding phase in the core plate matrix to form an aluminum-iron-silicon-calcium low-melting-point phase, which is gradually corroded under the erosion of the oxygen gun, which is the main damage mechanism of the core plate composite air-permeable bricks; the thermal shock resistance of the narrow slit part of the casting body is poor, and the brick body breaks horizontally during frequent thermal shocks, or steel penetrates directly through the micropores, resulting in bottom blowing failure or reduced flow rate, which is the main damage mechanism of the ceramic tube composite air-permeable bricks.

(2) Macro- and micro-structural design optimization and material innovation are improvement ideas for improving the service life of composite air-permeable bricks. Optimizing particle size distribution and improving resistance to infiltration and penetration by molten steel and slag are effective ways to extend the service life of dispersed composite structure breathable bricks. Introducing Cr2O3 and ZrO2 into the core plate can improve the core plate breathable brick’s resistance to infiltration by molten steel and slag, reducing slag erosion. Improving the thermal shock resistance of the cast body of ceramic tubular breathable bricks, reducing the diameter of the through-hole micropores, and ensuring the volume stability of the through-hole micropores at high temperatures are the development directions for this type of breathable brick.