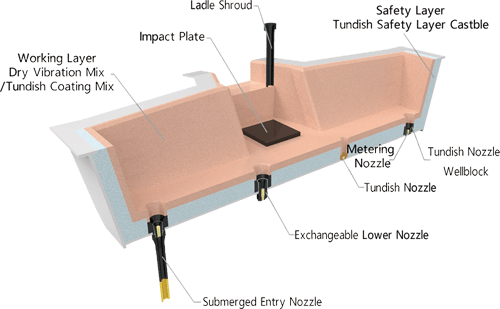

The tundish receives molten steel from the ladle throughout the steelmaking process and distributes it to the various molds through the tundish nozzle. This article discusses the metallurgical function of the tundish, the reasons for increasing tundish capacity, the critical height of the tundish, and the flow characteristics of the molten steel within the tundish.

1.Function of tundish

(1) Reduce the static pressure of the molten steel, maintain a stable molten steel level in the tundish, and smoothly inject the molten steel into the crystallizer;

(2) Promote the further floating of inclusions in the molten steel to purify the molten steel;

(3) Divert the molten steel. For multi-strand continuous casting machines, the tundish distributes the molten steel to each crystallizer;

(4) Store the molten steel. When changing ladles during multi-furnace continuous casting, the casting speed is not reduced, creating conditions for multi-furnace continuous casting. It can be seen that the main functions of the tundish are to reduce pressure, stabilize the flow, remove inclusions, store and divert the molten steel.

2.Metallurgical function of tundish

① Purification.

To produce high-purity steel, measures such as retaining walls and dams, argon blowing, and ceramic filters are used in the tundish to significantly reduce the content of non-metallic inclusions in the steel, and this has achieved significant results in production.

② Temperature Control.

To maintain the molten steel temperature below 5°C at the beginning, middle, and end of the tundish pouring process, close to the liquidus temperature, expand the equiaxed crystal zone of the ingot, and reduce centerline segregation, measures such as adding small pieces of scrap steel and injecting iron powder into the tundish can be used to adjust the molten steel temperature.

③ Composition Fine-tuning.

Aluminum, titanium, boron, and other cored wires are fed into the crystallizer through the center hole of the tundish plug rod to fine-tune the microalloying composition of the steel, improving the yield of easily oxidizable elements while preventing nozzle blockage.

④ Refining.

A double layer of slag is added to the tundish surface to absorb floating inclusions, or calcium wire is fed into the tundish to modify the morphology of Al₂O₃ inclusions and prevent nozzle blockage.

⑤ Heating Function.

Induction heating and plasma heating are used in the tundish to accurately control the pouring temperature of the molten steel within a range of 3°C to +5°C. The theoretical residence time of the molten steel in the tundish is the time the molten steel spends in the tundish from the time the ladle stream enters the tundish to the time it flows into the crystallizer. It is defined as: t = V/Q, where t is the residence time of the molten steel in the tundish (min); V is the molten steel volume or weight of the tundish (m³ or t); and Q is the molten steel flow rate in the tundish (t/min). For example, if the molten steel weighs 15 tons, the slab being cast is 200×1200 mm, and the casting speed V is min, then the molten steel flow rate Q is: Q = ××× = t/min. Therefore, t = 15 / = 6 min, meaning the molten steel stays in the tundish for 6 minutes. If the molten steel flows quickly from the nozzle to the mold within the tundish, inclusions won’t have time to float up. The general principle is: the longer the molten steel resides in the tundish, the more time inclusions have to float up, and the cleaner the steel will be. To increase the molten steel’s residence time, an effective method is to use a large-capacity tundish with a deep melt pool. In the 1960s, the typical tundish capacity was 6 tons; today, the maximum is 80 tons (Shougang Jingtang Iron and Steel Company’s tundish capacity reaches 80 tons, accounting for over 25% of the ladle’s total capacity). The tundish capacity should be as large as possible, depending on the ladle’s capacity. Using large-capacity, deep-melt-pool tundishes is the current trend.

3.Reasons for the increase in tundish capacity

(1) Prolonging the residence time of the molten steel in the tundish facilitates the floating of inclusions;

(2) Maintaining the casting speed when changing ladles maintains a stable tundish pouring process, preventing the liquid level from falling below the critical value, creating vortices and drawing slag into the mold;

(3) A stable molten steel level throughout the pouring process facilitates smooth operation;

(4) Increasing the tundish capacity helps reduce metal loss and lower operating costs. Therefore, pouring with a large tundish has significant advantages over a small one, producing cleaner steel with better surface and internal quality, and avoiding the defects caused by the unstable molten steel in a small tundish.

4.Intermediate height of the tundish liquid surface

As we all know, when a container is filled with water and the water flows out of the bottom hole, a vortex forms above the outlet when the liquid level drops to a certain height. This phenomenon also occurs in the tundish. There are two critical heights: one is the height at which the tundish is filled before pouring begins; the other is the height at which the molten steel level drops to at the end of the pouring process before pouring is stopped. Both have a critical height. If the molten steel level drops below this critical height, a vortex will form on the surface of the molten steel, drawing slag into the mold, increasing inclusions in the steel and rendering the product scrapped. The critical height can be determined through observation in a water model test. Depending on the tundish capacity, the critical height at which the molten steel level drops is generally 200-300 mm.

5.Characteristics of molten steel flow in the tundish

Generally, flow velocity, flow trajectory and turbulence intensity are used to describe the flow characteristics of fluids. Characteristics of tundish flow:

(1) The ladle flow acts as a “jet pump”, drawing the surrounding air into the tundish steel liquid and breaking it into small bubbles, forming additional circulation, and aggravating the secondary oxidation of the molten steel;

(2) The impact zone of the ladle flow entering the tundish is a highly turbulent area, which is prone to slag entrainment;

(3) Vortex formation. At the end of pouring, when the tundish liquid level drops to a critical height, a vortex is formed above the nozzle, entraining slag into the crystallizer. At the same time, the tundish flow is unstable, stirring the flow of molten steel in the crystallizer;

(4) Surface wave formation. When the tundish steel liquid level is unstable during pouring, ladle replacement and at the end of pouring, surface waves are easily generated, causing slag to be entrained into the molten steel.