In order to improve the purity of molten steel, the quality of ingots and production safety, in the construction of the dry material working layer of the tundish in continuous casting production, standardized operations and refined management measures such as separate material selection, layered control, and key reinforcement are adopted, which effectively improves the service life of the continuous casting tundish and ensures the stability of continuous casting production and the quality of ingots.

Make good preparations before construction

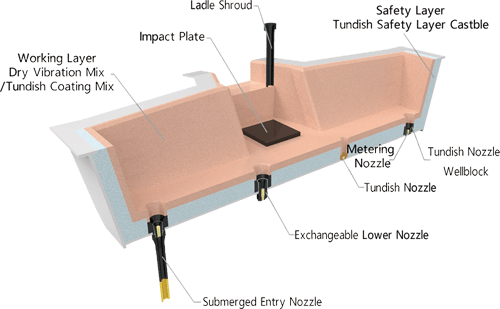

The tundish is a critical piece of equipment in continuous casting. Its construction quality, especially that of the tundish’s dry material working layer, directly impacts molten steel purity, ingot quality, and production safety.

Therefore, the following preparatory steps must be completed before tundish construction:

The first step is to inspect the tundish body. This primarily involves inspecting its cleanliness. This involves thoroughly removing any debris, such as old refractory material, steel slag, and oil stains, from the inner walls of the tundish to ensure there are no loose layers. Mechanical grinding or sandblasting should be performed if necessary to ensure a secure bond between the new lining and the body.

In addition, the structural integrity of the tundish should be carefully inspected. This includes checking for deformation and cracks in the cladding, ensuring the steel plate welds are secure, and ensuring that the drainage and ventilation holes are unobstructed.

Also, dimensional verification is crucial: measuring the designed dimensions of the tundish lining (such as depth, width, and nozzle location) to ensure they are consistent with the construction drawings to avoid dimensional deviations that could affect the molten steel flow field.

The second step is refractory material preparation. This primarily involves selecting refractory materials based on the characteristics of the steel grade (such as cleanliness requirements and temperature). For example, for dry siliceous and magnesia materials, inspect the packaging for damage, moisture, or agglomeration before use to ensure they are within their shelf life. Prefabricated parts (such as water inlets and impact bricks): Check the overall dimensions and appearance integrity (for cracks and damage).

Third, inspect tools and equipment. This primarily includes construction tools, such as vibrators, scrapers, templates, thermometers, and thickness gauges. Ensure that these tools are clean and free of oil and dirt.

In addition, the following equipment should be debugged. For example, the vibration table and baking equipment (such as gas burners and thermocouples) need to be debugged in advance to ensure normal operation.

Pay attention to key details in construction

Correct lining construction methods. First, the following points must be adhered to when constructing the dry material working layer:

First, construct in sections. The bottom working layer should be constructed first, followed by the mold for the working layer, followed by the wall and slag line working layers. The bottom working layer is typically approximately 100mm thick. Care must be taken to ensure it is evenly spread and leveled. When placing the working layer, ensure it is positioned properly, level, and aligned, with the left and right sides maintaining consistent spacing from the permanent layer. Pour the wall and slag line dry material to the required height according to design requirements, spread it flat, and tamp it firmly. Avoid adding too much material at once, which could result in a loose bottom vibration. The vibration time should be adjusted according to the material.

Second, bake the working layer. The baking time should be adjusted based on the material and the type of gas used. If gas baking is inefficient, the baking time can be extended appropriately.

Third, demolding and curing are performed. Demolding time should be determined based on the type of binder and weather conditions (low temperatures in winter shorten the demolding time). Demolding should avoid damaging the working layer due to the molded part. After demolding, the inner lining surface should be free of cracks and peeling, and have a uniform color.

Fourth, prefabricated parts should be installed. Prefabricated parts must be dry and clean. Before installation, apply refractory slurry (such as magnesia slurry) to the contact surfaces, ensuring the joint width is ≤2mm. Secure with wooden wedges or steel clips to prevent shifting.

Second, pay attention to the treatment of key areas. First, the nozzle area. Fill the area around the upper nozzle with dry material to ensure a tight bond with the cladding wall. After installation, check the seal of the lower nozzle, using the kerosene penetrant method to detect leaks. Second, the transition between the cladding bottom and the cladding wall should be rounded (R ≥ 50mm) to avoid stress concentration at right angles, which can cause lining peeling. Third, control the construction environment. Fourth, dust prevention and ventilation. Dust is generated during ramming or mixing, so wear a dust mask. Maintain good ventilation in the construction area to prevent the accumulation of harmful gases.

Safety measures must be strictly enforced

During the construction of the tundish dry material working layer, safety must be prioritized! First, personal protection must be emphasized. Workers must wear high-temperature-resistant gloves, dust masks, and goggles, and stay away from the tundish during baking to avoid burns.

Second, equipment safety must be ensured. Electrical equipment such as vibrators must be grounded to prevent electrical leakage. During baking, check the tightness of gas pipelines to prevent leaks and explosions.

Third, emergency response measures must be in place. If abnormalities such as cladding shell deformation or lining cracking are discovered during construction, operations must be stopped immediately, the cause analyzed, and corrected before continuing.

In short, the construction of the tundish working layer should be based on the principles of “zoning material selection, layered control, and key reinforcement.” Through standardized operations and refined management, the tundish service life can be effectively extended, ensuring the stability of continuous casting production and the quality of the ingots. In actual operation, flexible adjustments should be made based on the steel mill’s specific process parameters (such as steel grade and casting speed), and the construction plan should be continuously optimized.

More details about tundish furnace:

What is the function of a tundish?

A tundish is installed to prevent cross-contamination between an overflow pipe and a drain pipe. Unsanitary water from the drain pipe could theoretically enter the system if a tundish is not installed to block this.

What is the purpose of tundish in steel plant?

The role of tundish is to deliver the clean molten steel into the moulds at a desired throughput rate and temperature. Tundish flow modifiers help achieve desired steel quality by temperature homogenization, removal of non-metallic inclusions and prevention of nozzle clogging etc.

Why is a tundish called a tundish?

The word tundish originates from a shallow wooden dish with an outlet channel, fitting into the bunghole of a tun or cask and forming a kind of funnel for filling it.

How does tundish work?

The tundish is a safety device used in plumbing and heating systems. Its role is to safely direct water from an overflow or discharge pipe into a visible, external area, typically into a drain. This prevents water from causing damage to the system or the surrounding area by allowing it to be safely vented out.

What is the process of tundish?

Tundish is the last metallurgical vessel through which molten metal flows before solidifying in the continuous casting mold. During the transfer of metal through the tundish, molten steel interacts with refractories, slag, and atmosphere.