The tundish is a device for transferring molten steel between the ladle and the crystallizer. The main tasks of the tundish are:

(1) diverting molten steel. For multi-strand continuous casting machines, the molten steel is distributed to each crystallizer through the tundish;

(2) stabilizing the flow. Reducing the static pressure of the molten steel, maintaining a stable liquid level in the tundish, and smoothly injecting the molten steel into the crystallizer;

(3) storing molten steel. When replacing the ladle during multi-furnace continuous casting, the casting speed is not reduced to create conditions for multi-furnace continuous casting;

(4) purifying the molten steel. During a long casting time, the temperature of the molten steel is kept basically unchanged, which promotes the further floating of inclusions in the molten steel, prevents the molten steel from contacting with the air, and avoids oxygen and nitrogen absorption.

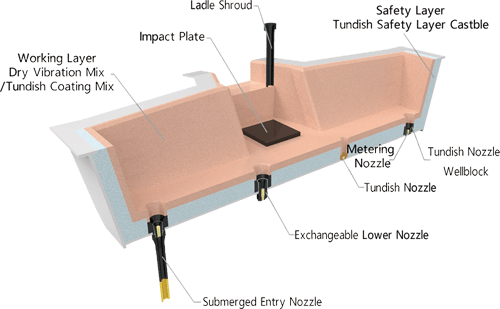

The refractory material of the tundish lining generally includes the following parts:

(1) Insulation layer (10-30 mm), which is adjacent to the steel shell of the tundish, usually made of asbestos board, insulation bricks or lightweight castables. The best effect is aluminum silicate fiber felt, which has low thermal conductivity and is easy to build.

(2) Permanent layer (100-200 mm), which is in contact with the insulation layer and is generally made of clay bricks. The integral permanent lining is the most common, and the castable is generally a high-aluminum or mullite self-flowing castable.

(3) Working layer (20-50 mm), which is in contact with the molten steel and is a key part. Insulation boards or coatings are now commonly used. Insulation boards are generally made of siliceous, magnesium, or forsterite; coatings are made of magnesium, magnesium chromium, or magnesium calcium. The coating is sprayed mechanically or applied manually.

(4) Seat bricks, which are embedded in the bottom of the tundish and used to install the tundish water outlet, are usually made of high-aluminum.

(5) The bottom of the ladle is made of the same material as the working layer. The working layer of the bottom of the tundish is easily damaged by the impact of molten steel and requires corrosion resistance and wear resistance. Generally, high-aluminum bricks or dense high-aluminum bricks and aluminum-chrome bricks are used, and special large-scale high-strength tar-magnesia bricks are also used. Zircon bricks or prefabricated blocks are used to strengthen the impact area of molten steel.

(6) The ladle cover covers the tundish and can play a role in heat preservation and molten steel splashing. The material used is clay or high-aluminum castables as the ladle cover.

(7) Slag retaining wall (weir), which is built in the tundish and can be a single wall or a double wall. The material of the slag retaining wall weir is usually high-aluminum bricks, which can also be made into prefabricated blocks. Its purpose is to retain. In order to improve the cleanliness of molten steel, a molten steel filter can also be set on the slag retaining wall.

Function of the middle package

The continuous casting tundish was originally used to keep molten steel warm, and its main purpose was to distribute and rectify the molten steel. With the successful development of molten steel slow cooling, molten steel reheating technology, argon sealing technology, gas stirring technology, and removal of non-metallic inclusions in molten steel, the continuous casting tundish has become the most important refining container in the final stage of the steelmaking process, and is developing towards large-scale.

1.Purification function

In order to produce high-purity clean steel, porous air-permeable bricks are installed at the bottom of the tundish, or porous tubular gas distributors are embedded between the working layer and the permanent layer, or porous bricks are installed on the slag retaining wall for argon blowing, so that argon bubbles float evenly from the bottom to promote the removal of inclusions. These devices can eliminate hydrogenation of molten steel in the initial stage of pouring, reduce oxide inclusions in molten steel, and reduce defects caused by Al2O3 inclusions on tinplates.

2.Temperature control function

In order to make the temperature difference of molten steel in the front, middle and late stages of the tundish less than 5°C during the pouring process, close to the liquidus temperature, expand the equiaxed crystal zone of the ingot and reduce the central segregation, measures such as adding small pieces of scrap steel to the tundish and spraying iron powder can be taken to adjust the molten steel temperature.

3.Ingredient fine tuning

The center hole of the tundish plug rod is used to feed aluminum, titanium, boron and other core wires into the crystallizer to achieve fine-tuning of the micro-alloy components in the steel, which not only improves the recovery rate of easily oxidizable elements but also avoids nozzle blockage.

4.Refining functions

Add double-layer slag on the surface of molten steel in the tundish to absorb the floating inclusions in the molten steel, or feed calcium wire in the tundish to change the morphology of Al2O3 inclusions to prevent nozzle blockage.

5.Heating function

Induction heating and plasma heating are used in the tundish to accurately control the pouring temperature of molten steel within ±3-5°C. The tundish is heated at the beginning of pouring and at the end of pouring when changing the ladle to compensate for the decrease in molten steel temperature and keep the molten steel temperature near the target, which is conducive to the stability of the pouring operation and improves the quality of the ingot. At the same time, during the normal pouring period, proper heating can compensate for the natural cooling of the molten steel. The heating method uses induction heating and plasma heating.

Tundishes are developing towards large-scale

At present, the capacity of the tundish of slab continuous casting machines is gradually developing towards larger sizes. The advantages of increasing the capacity of the tundish are as follows:

(1) Prolonging the residence time of molten steel in the ladle is conducive to the floating of inclusions;

(2) The casting speed is not reduced when changing the ladle, so the pouring of the tundish is kept stable to prevent the liquid level from falling below the critical value to form a vortex and draw the slag into the crystallizer;

(3) The molten steel level is stable during the entire pouring process, which is conducive to smooth operation;

(4) The increase in the capacity of the tundish is conducive to reducing metal loss and lowering operating costs.