Furnace age, also known as furnace lining life, refers to the intermediate frequency furnace lining from put into use to replace the new lining to stop a furnace service period of the total number of steelmaking furnace. It is a comprehensive index to measure the production level of IF furnace. Therefore, the age of the furnace not only represents the level of technical equipment, process operation, production management, but also determines the productivity of the intermediate frequency furnace, the production cost of high and low.

As we all know, the medium frequency furnace has a small size, light weight, fast heating, high efficiency and so on. Favored by foundry enterprises. Mainly used to melt castings and certain precision castings with steel, in recent years it is also used to melt stainless steel. At the same time with medium frequency furnace melting, can avoid the problem of increasing sulfur and phosphorus. So that the liquid iron in the P is not greater than 0.075%, S is not greater than 0.5%.

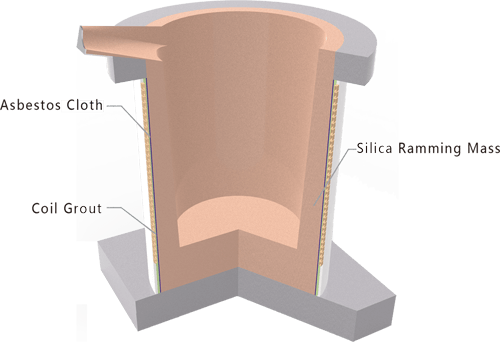

Medium frequency furnace refractory material is relatively simple, generally using knotted material; also used in crucibles (i.e., shaped furnace chamber).

1.Correct selection of high quality furnace lining materials suitable for melting

Must be very clear to everyone, engaged in melting, especially engaged in casting can not be separated from the furnace lining materials, furnace lining materials, chemical composition and physical and chemical properties of the service life of the furnace lining has a great impact.

At present, the commonly used furnace lining material technology materials can be roughly divided into the chemical properties: acidic, alkaline and neutral three categories: according to the physical properties can be divided into non-stereotyped materials, stereotyped materials of two categories.

Characteristics of furnace lining materials

The chemical composition and physical and chemical properties of the furnace lining material have a great influence on the service life of the furnace lining. Impurities in refractory materials can form low melting point compounds at high temperatures, thus reducing the refractoriness of the refractory material. With the increase of impurity content in refractory material, its refractoriness decreases, and the service life of the furnace lining also decreases with the decrease of refractoriness.

In order to extend the service life of the furnace lining, theoretically the higher the purity of the refractory material, the better. In production practice, the high purity of refractory materials by the reduction of mineral resources and reduce the price is rising again and again. In order to make the furnace lining materials have a more ideal cost-effective and practical, according to the current commonly used, common a little bit of the furnace lining refractory materials with the actual situation (physical and chemical indicators), in the furnace lining refractory materials with the addition of a certain amount of other materials, so that the furnace lining materials at high temperatures under the state of the production of new compounds and derivatives of compounds, can be a better solution to the problem of refractory refractory furnace lining materials. In other words, make full use of the existing resources, more development of composite furnace lining materials applied to the melting of the production practice.

Different materials of refractories due to their different physical and chemical properties, their adaptability to the melting conditions are also different, such as resistance to slag erosion, resistance to rapid cold and heat performance. Therefore, the service life of the furnace lining varies greatly. Especially when melting high manganese steel, not only the melting temperature is high, and the melting conditions are also relatively poor, Fe, Si, Ai, Mn, C, slag in the slag, CaO, S02, Fe0 and other elements of the furnace lining erosion is very serious, resulting in the service life of the furnace lining is greatly reduced.

To melt high manganese steel, high carbon steel, for example, daily we often use quartz sand furnace lining materials can not take on this heavy responsibility. Due to the low refractoriness and large volume expansion rate of quartz acidic furnace village materials, used in steelmaking, the service life of the furnace lining is low. However, due to the low cost of quartz sand, in melting cast iron is still applied, especially continuous operation (crucible temperature is maintained at 800 ~ 1000 ℃), its life expectancy of up to more than a hundred furnaces. Therefore, engage in cast iron almost all use quartz furnace lining materials and the use of magnesium, magnesium aluminum, magnesium chromium, such as dry knotted material (that is, we often say that the alkaline furnace lining materials) can be a better solution to the low refractoriness of the furnace lining materials this problem.

2.Elements not to be overlooked to improve furnace age

2.1 Influence of volume on the service life of the furnace lining

The static pressure of the steel on the furnace lining varies with the size of the furnace. The service life of the furnace lining decreases as its capacity increases.

At present, most of the melting equipment we use is with non-vacuum induction furnace, with the increase of furnace capacity, the liquid steel on the wall of the furnace lining of the static pressure increases. Generally speaking, 1 tons of furnace lining of the static pressure is 150 kg: 10 tons of furnace lining wall of the static pressure is 500 kg. It can be seen, the larger the capacity of the furnace, the furnace village wall to withstand the static pressure is also greater. Therefore, the steel in the large furnace is more likely to penetrate along the capillary channels of the refractory lining to the furnace lining wall, so that the furnace lining is quickly destroyed. As the capacity of the furnace increases, the frequency of the power supply used decreases. The lower the frequency of the stirring force is greater, the furnace lining wall of the impact force is greater. Electromagnetic stirring force in the liquid steel and the square root of the frequency of the power supply is inversely proportional to the 3-ton furnace lining wall withstand the scouring force of 150 kg. Therefore, with the increase in furnace capacity, the furnace lining wall of the scouring force also increased.

2.2 Erosion of furnace lining materials by the temperature of melting

When the melting temperature is greater than 1700 ℃ or more, the viscosity of the liquid steel will also drop sharply, the destruction of the furnace lining will accelerate the speed of the lining life will be greatly reduced. Therefore, control the melting temperature will be directly related to the service life of the furnace lining.

It can be seen, in the magnesium refractory materials to add a certain amount of other materials can be a better solution to the thermal expansion of pure magnesium furnace lining materials.

2.3 Influence of the composition of the liquid steel on the service life of the furnace lining

Steel in the Fe, Si, Ai, Mn, C, and even metal vapor, CO gas, including CaO in the slag related to fine SiO2, FeO along the refractory capillary pore; infiltration of refractory internal. These infiltration components deposited in the refractory capillary pore channel, resulting in the physical and chemical properties of the refractory work surface and the original refractory matrix discontinuity, in the operation of the temperature of the rapid change will appear cracks, spalling and structural loosening, strictly speaking, this damage process than the dissolution of the damage process is much more serious.

2.4 Erosion of furnace lining materials by slag

With the increase in furnace capacity, the proportion of heat dissipated from the surface of the liquid steel decreases, the slag temperature is higher than that of the small capacity furnace, and the mobility of the slag is also better than that of the small capacity furnace, thus increasing the erosion of the furnace lining, and the large-scale induction furnace is mostly used for steel slag mixing out of the method of steel production, which requires the slag to have a good mobility in order to adapt to the conditions of the steel production. Therefore, the slag line part of the erosion is serious, which is caused by the service life of the furnace lining down another reason. Due to the above reasons, the service life of large induction furnace lining is lower than that of small and medium-sized induction furnace, and the thickness of crucible lining should be increased appropriately in terms of improving the service life of furnace lining. However, with the increase of the thickness of the furnace lining wall, the resistance value increases, the reactive power loss increases and the electric efficiency decreases. Therefore, the thickness of the furnace lining wall is limited to a certain range. Therefore, a reasonable wall thickness must be selected, which ensures high electrical efficiency and the service life of the furnace lining.

The alkalinity of the slag should be compatible with the furnace lining material. Magnesium furnace lining material can be eroded by high CaO slag and SO2 slag. The amount of CaF in the slag should be controlled. Excessive CaF will erode the alkaline furnace lining and cause premature melting in the slag line area.

Alkaline slag is suitable for magnesium furnace lining, acidic slag is suitable for quartz furnace lining, magnesium-aluminum furnace lining can only use weakly alkaline or neutral slag. When the alkalinity of the slag is low, the magnesium furnace lining erosion is more serious, the life of the furnace village is reduced; on the contrary, when the slag alkalinity is high, the erosion of the furnace lining is more slight, the life of the furnace lining is relatively improved when the slag fluoride ions, metal manganese ions, etc. is high, the magnesium furnace lining erosion is also more serious, and the life of the furnace lining is reduced.

When slagless melting is carried out under vacuum, the service life of the furnace lining is greater than that of non-vacuum melting.

This proves that the slag will make the furnace lining service life decline. Therefore, according to the nature of the slag should choose the appropriate furnace lining materials.

2.5 Influence of knotted density of furnace village on the service life of furnace lining

The knotted density of the furnace lining directly affects the service life of the furnace lining. Therefore, selecting the right lining material is only the basis for improving the age of the furnace, then improve the lining of the knotted density is the key to improve the age of the furnace.

In order to get the knotted lining (either dry or wet), the following must be done:

1.knotting the bottom of the furnace: three to four times the packing, knotting;

2.Knotting furnace wall: knotting layer by layer, the thickness of each layer of filler can not be greater than 15 centimeters;

3.each layer of knotting, the knotting surface must be scraped, and then hit the next layer, so that the stubble fully combined, from the root to eliminate the phenomenon of fault. Especially the combination of furnace bottom and furnace wall.

4.knotting before the lining, must be carefully and cleanly cleaned up the scene. Never allow the iron containing debris mixed into the furnace lining materials, so as to avoid the furnace lining materials mixed into the iron debris in the potential voltage under the action of the formation of poly iron, iron condensation phenomenon caused by wear furnace.

The sintering quality of the lining is directly related to the sintering quality. Requirements for knotted sand material particle size uniform distribution does not produce coarse and fine segregation, knotted sand layer of high density. In this way, the chance of cracks after sintering is reduced, which is conducive to improving the service life of the crucible. The most common defects in the knotting process are low density, uneven and coarse and fine grain size sand layering (which is often referred to as grain size segregation) and other phenomena. This is especially noticeable in the case of low water content or dry kneading.

2.6 Effect of the degree of sintering of the furnace lining on the service life of the lining

The knotted density of the furnace lining directly affects the service life of the furnace village, while the sintering process of the lining determines the strength of the furnace lining. Therefore, the sintering of the furnace lining from the low-temperature zone of the heating rate to the final sintering temperature and holding time, have an important impact on the sintering quality of the furnace lining. The escape rate of water vapor during low temperature baking should not be too fast to avoid early cracks in the sand. The source of moisture in the furnace lining is the water adsorbed by the sand, water of crystallization and additives decomposition of the water released, in 800 ℃ below all of these water excluded. So the rate of heating should be controlled in this interval. The larger the capacity of the furnace the more to reduce the rate of heating, in order to avoid the rapid escape of water vapor from the sand. The sintering temperature and holding time should be selected accordingly for different materials in order to get the ideal sintered structure. When sintering at high temperature, the sintered structure of the furnace lining is the basis for improving the service life. Insufficient sintering temperature and insufficient thickness of the sintered layer will significantly reduce the service life of the furnace lining. In order to obtain a long service life of the furnace lining, it is necessary to obtain an ideal sintering structure in advance.

2.7 Furnace replenishment is one of the important measures to improve the age of the furnace

The erosion of the furnace lining must be checked frequently after the furnace is opened. When the lining of the large cracks that should be repaired (small cracks do not need to be repaired, it can be in the high temperature state of their own closure).

Furnace, should be damaged at the surface layer of the first pick off, with 5% of the boric acid water coated wash, and then the same material with the furnace material set in the damage, with a rubber hammer to play it solid.

Open the furnace is completed, the top of the furnace cover, to avoid a sharp drop in temperature of the furnace lining. Furnace lining rapid heat and cold, such as normalizing, seriously affecting the organization and structure of the lining and shorten its service life.

Sum up

1) Furnace lining refractory quality improvement is the basis of the lining of the knotted dense, optimize the steelmaking process, reduce the temperature of steelmaking, timely replenishment of the furnace is the key to improve the age of the furnace.

2) Reasonable use of the appropriate amount of binding agent, binder, additives will also improve the overall quality of the furnace lining. Such as: in the magnesium furnace lining material to add a certain percentage of high aluminum material, so that it is generated at high temperatures under the action of magnesium-aluminum spinel phase, is also conducive to improving the service life of the furnace lining.

3) Improve the age of the furnace can reduce production costs, increase production, reduce the labor intensity of workers. At the same time, it also drives and promotes the production technology and management.