1.The life of the skateboard is relatively low.

At present, the material of the domestic converter skateboard is mostly aluminum-zirconium carbon. As the material of the ladle skateboard, it has high strength, good thermal shock resistance, and excellent erosion resistance and corrosion resistance; But for the converter skateboard to block slag technically, the service life of the skateboard is relatively low.

2.The life of the tap hole needs to be further improved.

The life of the tap hole is one of the important indicators of the converter sliding plate slag blocking technology. The tapping is caused by the frequent direct erosion and violent erosion of high temperature molten steel and high oxidizing slag, and the effect of rapid cold and hot heat. The mouth is easily damaged. The length of its life directly affects the converter smelting cycle, steelmaking productivity and slag retaining effect, which in turn affects the quality of steel. The integrity of the tap hole directly controls the amount of slag in the converter, and has a direct impact on the alloy yield and the next refining process (LF, RH, etc.)

3.Improve and optimize the material and structure of the skateboard to greatly increase the service life.

Aiming at the general problems existing in the material of converter skateboards, improving the overall performance of the skateboards such as oxidation resistance, wear resistance, thermal shock stability, corrosion resistance, etc., The aluminum-zirconium-carbon body composite zirconium inlay ring technology is used to make the skateboard integrated. The service life is greatly increased, greatly reducing the labor intensity of workers, and providing a strong guarantee for the implementation of the fast-paced steelmaking process of the converter in the steel plant.

4.Measures to improve the overall life of the tapping port.

During the converter tapping process, the molten steel passes through the tapping port to the ladle. The refractory material of the tapping port is gradually melted under the washing of the high-temperature flowing molten steel, making the inner hole of the tapping port appear “inverted horn (” The upper mouth is small and the lower mouth is large)” reaming. Since the tapping hole is assembled by the set brick and the end brick (C brick) as a whole.

More details about BOF Furnace

What does BOF mean in steel production?

Basic oxygen furnace

The basic oxygen furnace (BOF) is a vessel used to convert pig iron, of about 94 percent iron and 6 percent combined impurities such as carbon, manganese, and silicon, into steel with as little as 1 percent combined impurities.

What is the BOF method?

The basic oxygen furnace (BOF) process is a method of primary steelmaking in which carbon-rich hot metal or pig iron, produced by a blast furnace, is made into steel. It was originally developed in the early 1950s in the Austrian cities Linz and Donawitz, which is why it can also be referred to as the LD process.

What are the different types of BOF?

BOFs include conventional top-blown furnaces, bottom blown furnaces, and various mixed blowing configurations and inert gas bottom stirring modifications.

What type of slag is required for BOF steel making process?

On the other hand, BOF slag mainly contains CaO added as a refining agent, and SiO2 and iron oxides produced by oxidation refining process. The EAF slag is classified into two types, oxidation slag and reduction slag, which are produced during steel refining and reduction of iron oxide to metallic iron, respectively.

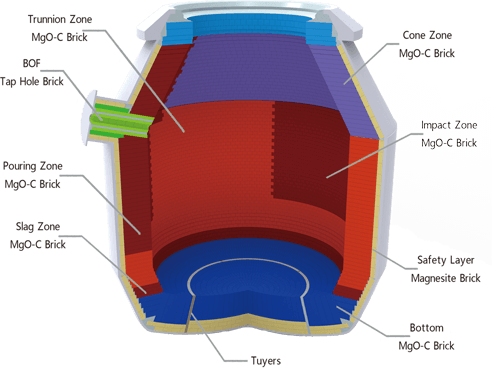

What type of refractory bricks are used in BOF vessels?

MgO-C is now the widely accepted refractory used as the main working lining. With the BOF as the most important steel making application in terms of refractory tonnage and the new demands for special grades of steel, the refractory is exposed to higher oxygen volume flows and new process operations.